How might we design an affordable, accessible, and intuitive water testing solution using ORP technology for nonprofits and communities who need these solutions most?

research

literature review

- using an ORP sensor to find chlorine level in parts per million (ppm)

- use contexts: case studies in Ghana and Honduras

- opportunity for impact through packaging

competitive analysis

- understanding of current landscape and what we might contribute to address user needs

- combining and/or rethinking current features

interviews

- motorcycles are typical transport means for technicians, introducing limited storage capacity as a constraint

- testing could be completed at the source water site, site of chlorination, and access/endpoints

Our initial approach to research was heavily focused on qualitative methods with potential users of the device. However, direct access to potential users was not possible due to the emphasis on low-income settings on a global scale. We consulted with three WASH (Water, Sanitation, and Hygiene) experts which provided limited context for our target users and their environment. To address this gap, we supplemented the process with reading about various use contexts and explored the competitive landscape of water testing devices. Consequently, the direction of design choices shifted from user-based to research-informed decisions and frequent testing of assumptions.

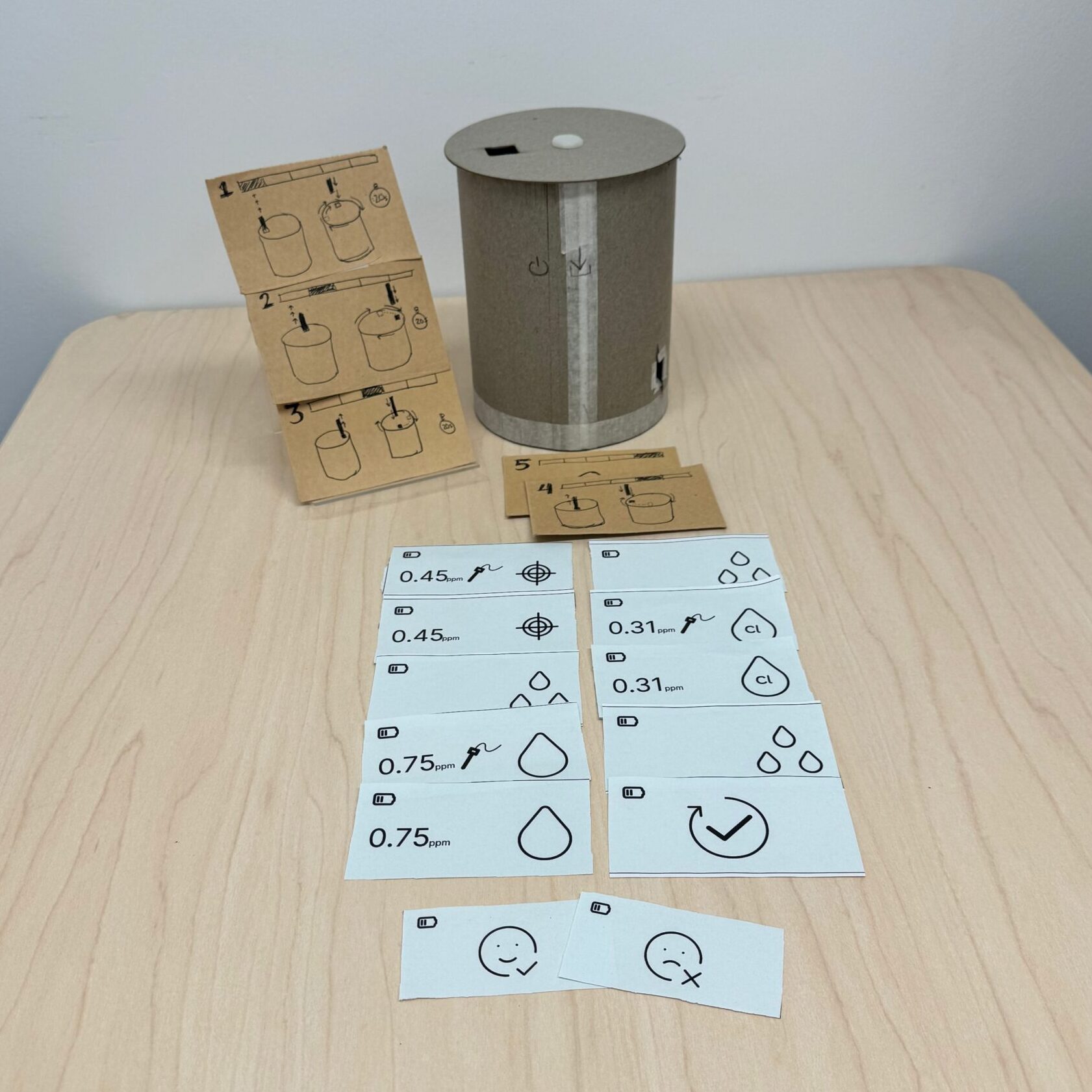

prototyping

user testing

Intuitive products streamline complexity, they help us navigate complex territories. We found users with no familiarity with water testing or ORP. Their feedback highlighted the unintuitive. Then we situated the device in context with more informed users to determine what experts need.

What do experts need? Is our design efficient and durable for use in the field?

prototype d

Self-Described 'Technical Luddite'

- no context for the device or its use was given

- symbology for step completion was misinterpreted as an indication the water was drinkable

- source versus treated water was not successfully communicated through UI

- rinsing was not successfully communicated

prototype g

Design Engineer

-

Device context was understood before the test, though the process was unknown

-

icons on instructions and interface must be identical

-

rinse procedure was not successfully communicated

-

LEDs of different colors seemed to unclearly communicate meaning

-

left to right progression felt intuitive

prototype h

WASH Experts at PATH

- two sessions completed–no context given before session I, context provided for session II

- interface VI was unanimously preferred

- importance of rinsing needs more emphasis and the procedure should be more specific

- calibration is confusing; hand fit works well

- request for more use of language

- more distinction between segments

the goat

all our work culminates into this design

intuitive

- error free physicality

- waterproof, low-cognitive instructions

accessible

- 3D printed

- no dependence on manufacturing

- minimal assembly

affordable

- water testing is generally unaffordable

- ORP is less than $150 including electronics, sensor, and filament